WHEEL GUIDE

Guide

Points on Choosing Wheels

Choose the Best Wheels for Your Beloved Car.

Ever feel like this when you want to buy new wheels: “I want to make my wheels look awesome! But, which wheels should I choose...?”

It can become quite complex when it comes to choosing the right wheels for your vehicle, while also trying to keep up with the new trends. Taking these things into consideration, we encompassed a wheel specs chart helper and pointers to assist in directing you to the best wheels for your vehicle.

Dress up your vehicle with the best wheel matches using the reference guides provided.

Learn the Names of Each Wheel Part!

Let Us Guide You to the Best Sizes For Your Wheels & Tires!

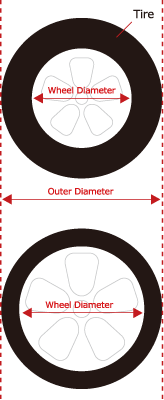

- Inch-Up Sizing is the New Trend.

- When changing a wheel there is the “Plus Sizing” or “Inch-Up Sizing” technique that can be used to keeping natural wheel sizes without causing damage to the wheel or vehicle. With Work wheels you can keep your vehicles natural wheel size while also keeping your wheels in style. For example, the natural wheel size is 19”, you can choose any stylish 20” or 21” wheels.

- Guidelines for Going Out of Natural Tire Size.

- Inch-Up sizing is possible to do but must be proceeded with caution in regards to outside diameter of the tire when choosing to do this method. This in part is that the natural wheel and tire sizes were assembled together to fit the specifications of your vehicle. Going out of natural tire size can cause potential risk of speedometer and odometer functions, as well as severe damage to vehicle maneuverability.

- Significance of Consistent Thin Tire Checks.

- The tires on your vehicle will inevitably flatten when Inch-Up Sizing. Thus, when the tires flatten the shape of tires changes as well. This overall increases the maneuverability and gives your vehicle a more sporty feel. However, extreme inch-up sizing to wheels can cause extreme tire flattening. Please be aware that in some cases there may not be wheels that match tires with over inch-up sizing.

There are 3 types of wheel constructions. Choose the Best Wheel Piece According to Each Feature!

Construction

Barrel and disc constructed as a unit. Usually referred to as European monoblock construction.

Advantages

The disc and barrel is molded together creating a 1-piece wheel unit. Thus, it is able to keep long-lasting rigidity. The 1-piece wheel is also simple and easy to manufacture, making it a cost efficient product for both manufacturers and consumers.

Construction

Barrel and disc are molded and constructed separately. The new method of jointing parts of the 2-piece wheel together is through welding.

Advantages

The offset can be specially altered millimeter by millimeter to your ideal position of the disc face.

Construction

A 3 layered unit, consisting of the disc centering the outer barrel and inner barrel held together with pierce bolts.

Advantages

Outer barrel, inner barrel, and disc face is constructed with different materials and manufacturing processes, giving it flexibility and excellence in its functions and designs.

Different Wheel Structures According to Your Style!

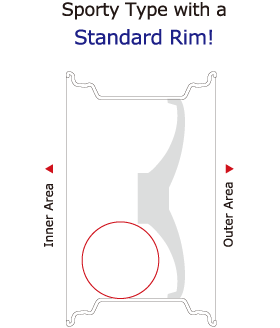

Standard rims are basic wheel constructions. The inner area has a large amount of space to install a large brake rotor, making it advantageous for equipping a big calliper. We recommend this type for those looking for a sporty look.

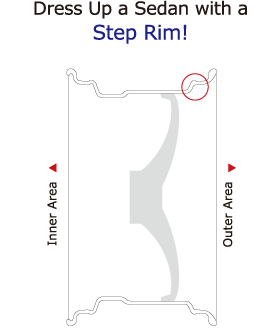

The step rim is a reverse rim type, with the outer lip design of the rim being the determining feature.We recommend this type of wheel structure for dressing up a sedan.

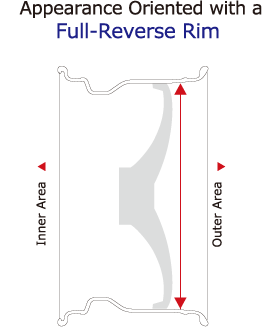

The full-reverse rim has the complete opposite structure from the standard reverse wheel. This wheel has more flexibility in disc face sizes, making it easier to visibly see the designs on the disc face. We recommend this wheel for those who have a strong preference on aesthetics.

Understanding the Rim Width & Offset is Key to a Beautiful Combination!

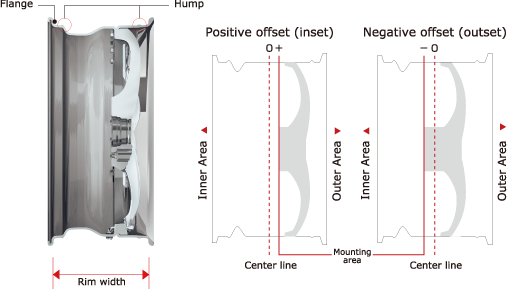

- What is Rim Width?

- The rim width in essence is a size indicator for the depth of the wheel. The tire width must match both sides of the rim width when the wheel is mounted onto the tire. With Work Wheels you can choose a rim width as deep as 0.5”.

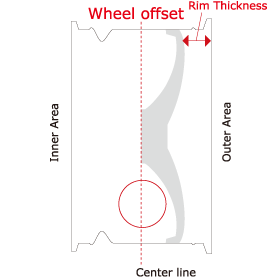

- What is offset?

- The offset is a measurement(labeled in mm) defining the distance between the “center of the rim” and the “mounting surface on the car(disc part of the wheel).” When the hub mounting surface is toward the front, or inside the car fender, from the rim centerline it is referred to as positive offset (+), and when the hub mounting surface is toward the back, or outside of the car fender, it is referred to as a a negative (-) offset. When the offset is positive the wheel sits inside the body of the car and with a negative offset the wheel sticks out from the car body.

-

<How to Adjust the Rim Width & Offset>

- Selecting a Rim Width Adequate with Tires

- Let’ s take a look at information about tires first. There have been more cases in which choosing thicker tires lead to better performance and overall appearance than basic tires. Determining whether a wheel can be mounted onto a tire depends on the thickness of the tire.

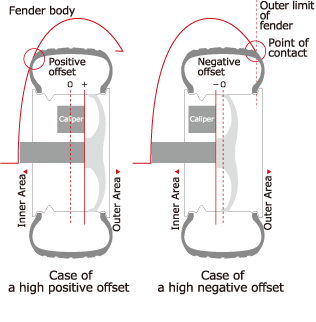

- Setting the Offset.

- Now we know how to determine the rim width, the next step is understanding the relationship between the calliper (brake) in the inner area and the fender in the outer area. If the positive offset is set too high on a rim with large wheels then the wheel will interfere with the inside of the fender. On the other hand, if the negative offset is too high on a rim with large wheels then the wheels will touch the fender and will protrude from the car body. When calculating the offset of your wheels, it is best to consider a good balance between the inner and outer areas due to tires and rims that stick out from the fender, which is considered a Road Traffic Law violation.

Other than just choosing a wheel design, there are many points that must be taken into consideration when customizing your wheels, such as coordinating the wheel size(inches/rim width/offset) with the vehicle. Now we will explain a few wheel setting methods to adjusting and choosing the right wheel rim width and offset for your vehicle and tires.

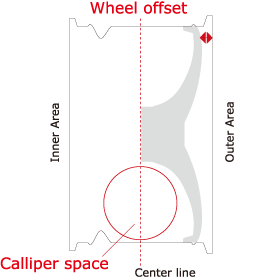

Disk Type Changes Depending on the Needs of Your Car, From the Big Calliper to the Deep Rim!

【R disk】Big Calliper Compatible

【R disk】Big Calliper Compatible

The back of the R-Disk ensures plenty of space to prevent any interferences with the calliper. This disk is best for sports and race car drivers who want to install a large brake system.

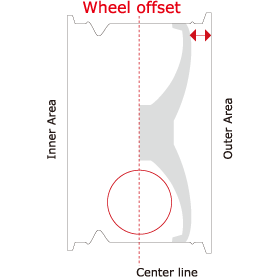

【A disk】Standard Compatible

【A disk】Standard Compatible

The A-Disk is a standard disk type compatible with general brake suspensions. This disk is compatible with a wide range of vehicles, and is best for those who are new to customizing wheels or are looking to make minor design changes to their wheels.

【O disk】Rim Thickness Compatible

【O disk】Rim Thickness Compatible

The O-Disk in comparison to the A-Disk has the same offset values, however, differs in its thickness of the outer rim. This wheel design is perfect for drivers who prefer the deep dish look.

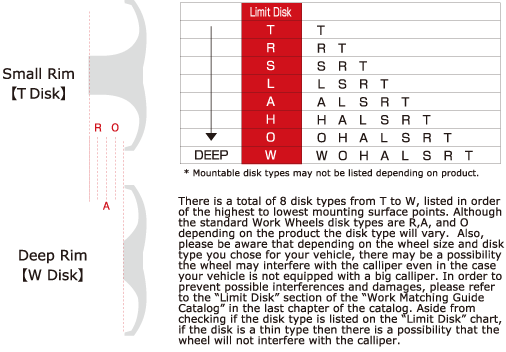

There’ s more than just R,A,and O disk types!

There is a total of 8 disk types from T to W, listed in order of the highest to lowest mounting surface points. Although the standard Work Wheels disk types are R,A, and O depending on the product the disk type will vary. Also, please be aware that depending on the wheel size and disk type you chose for your vehicle, there may be a possibility the wheel may interfere with the calliper even in the case your vehicle is not equipped with a big calliper. In order to prevent possible interferences and damages, please refer to the “Limit Disk” section of the “Work Matching Guide Catalog” in the last chapter of the catalog. Aside from checking if the disk type is listed on the “Limit Disk” chart, if the disk is a thin type then there is a possibility that the wheel will not interfere with the calliper.

Select Any Style Wheel of Your Liking From a Wide Variety of Colors!

Choose from a wide variety of disc face colors of chrome-plated to diamond cut rim polished finishes and more. Each design has its own color line up, so dress up your wheels the way you want from the vast color variations listed at the bottom of the specs chart of each product. Disc colors are not the only items you choose, you can also choose the rim color of each design.

Check the Price of Your Selected Wheels!

After using the “Work Wheels Matching Guide Index” in the back of the catalog to select your desired wheels, the next step is to check the price. Depending on the size, rim, width, disk and rim color the products may be the same but prices may vary. We can assist you in choosing the best match for your vehicle and needs within your budget.

- JWL

- Acronym for Japan Alloy Wheel. A wheel with a JWL logo indicates the wheel is a light wheel alloy for passenger vehicles and has passed safety standards tests. General safety tests such as weariness and durability are the responsibility of the manufacturer themselves.

- VIA

- Alloy wheels with this engraving have officially passed and received confirmation from a third party, which is the Japan Light Alloy Automotive Wheel Testing Council, that determines whether the wheel passes the JWL and JWL-T standard safety tests.

- ETRTO

- ETRO is the acronym for the European Tyre and Rim Technical Organization .

- JWL-T

- Safety standards that apply to light alloy disk wheels for trucks and buses. Wheels that do not have the JWL, JWL-T official mark will automatically fail vehicle inspection. Low weight wheels that are higher than average passenger wheels must have official JWL,JWL-T engraving. The “T” in JWL-T stands for Truck. These are basic and standard requirements for the JWL general safety test.

- TÜV

-

TÜV are initials for the German word, Techinischer Uberwachungs-Verin, meaning Technical Inspection Association. In other words, the headquarters of the TUV located in Germany has an international third party organization. This is an authorized organization that administers safety vehicles and vehicle parts testing certifications that encompasses all areas of mobility. Almost all automobile related industries residing within Germany are certified, and gives an appeal of top-class safety.

* All Work Wheels Japan products are TUV licensed and approved products, that have been through strict tests.

Equip Your Car With Work Wheels, Created with the World’ s Most Advanced Technology!

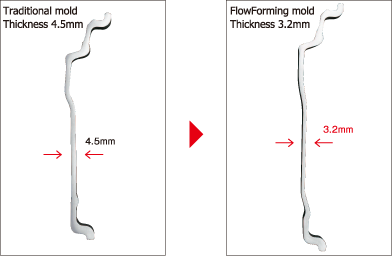

WORK FLOWFORMING TECHNOLOGY

WORK FLOWFORMING TECHNOLOGY

The FlowForming manufacturing method is used on the inner barrel of the WORK EMOTION CR kiwami. After the barrel is casted, the mold is stretched out while an immense amount of pressure is applied to it creating a new, stronger, and elongated barrel mold. This manufacturing method is called the Flowforming method. Using this manufacturing method makes the macrostructure of the forged aluminum more defined. Furthermore allowing the forged metal flow rim more thick and light in weight. This in return heightens the need for the "pulling strength" and "sticking strength" of the inner rim. At the same time the performance of the outer rim’ s durability and traditionally forged wheel functions are vastly increased.

The 3D coating brings out a rich, high-class on the disc face.

The Super Chrome 3D Coating is a high quality color we take pride in. The pre-painting process of 3D Super Chrome coating is not only on the traditional disc face but also on the spokes and pierce bolt joints areas, giving it a mirror-like brushed finish. The chrome coating also makes the wheel shine. The 3D coating is performed by our skilled craftsmen that tend to each and every detail by hand. You can see the excellent shine of our skilled craftsmen for yourself.

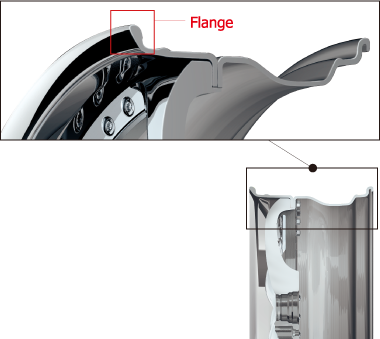

“Work Solid Rim”

We have discovered the answer to everyone’ s wish with creating a wheel that can give both a safe and long lasting car life and the abundance of styles with a long life expectancy. The answer to this is called the “Work Solid Rims.” While enhancing the strength and rigidity of the flange, another characteristic of this rim technology is that it is TUV certified and the shape of the hump meets all ETRO standards, amplifying its safety. Due to the process of the main unit not being machined when molded, the amazing coexistence of both an enhanced product and high credibility in terms of safety. We utilize the world’ s most unique technology to create high quality rims.

* Hump: In the case of problems with wheel functions, low air tire pressure or due to rim shape the rim gets caught in tire beads may be the causes.

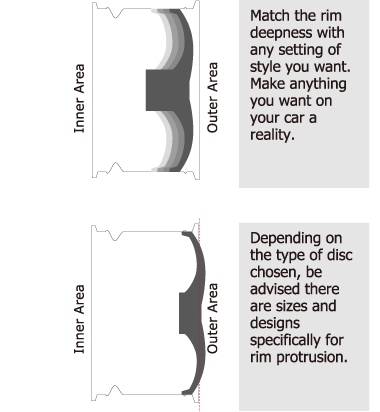

Making Your Styling Ideas a Reality.

Nowadays, there are wheels that have functions and effects for certain types of vehicles in its respective categories such as minivans, compact cars and imports. There is a significant difference in how to dress-up each category. We provide an abundance of colorful disc face lineups to satisfy all drivers with different tastes.

Caution is Advised For Protruding Disks For Minivans.

Choosing and matching a disc from our vast lineup depends on the type of style the driver is aiming for. However, there are cases where the driver matches an offset to coordinate with a style with the rim protruding from the disc and fender. Especially nowadays, this look has been seen on numerous minivans. Be sure to thoroughly check the specs chart of each wheel when selecting, along with consulting with one of our experts before purchasing your wheels.

“I want to bring out more of my personality and emphasize originality.” In response to these drivers we’ ve established an abundance of optional items for each wheel brand. Exchanging pierce bolts, air valves, or even center caps is possible. Dress up your wheels with the tiniest of details with these accessories.

Repair Parts for the Unexpected!We provide replacement parts for center caps, center covers, valves, decals, and other accessories incorporated with Work Wheel Japan products. Depending on whether parts were stolen, damaged, or unclean we will match exchange parts with decal colors.

*Please be aware some items may be discontinued.

The wheels of a car can drastically change its image; from sporty, to elegant and to even gorgeous. Wheels are the most important item to giving a car its personality. Whether to cater to the requests of each customer or to set defined perimeters to the products produced has been a major topic in the wheel maker industry. We, Work Wheels Japan, as a wheel maker industry have cultivated know-how in the long years we have been in business. We are confident in our abilities to create wheels that can cater to your needs. As an example, we are proud of our world leading technology in wheel surface processing technology.

The top surface and sides of the disc are painted black, then the lip of the rim and the outer area of the barrel is machined to a new clear cut rim design. The disc face undergoes a machining design program that gives it a look like an edge of a sword.

This is a finish that enhances the natural aluminum on the disc and brings out fine details of the design. With almost all of our wheels being handcrafted, we never replicate the same wheel with our craftsmanship. A clear coating finish is applied to strengthen corrosion-resistance for a longer lifespan and easier maintenance.

The front of the disc design is brush finished with the sides being buff finished, exhibiting a high quality and high-class feel. For finishing touches, a clear coating is applied to strengthen corrosion-resistance for a longer lifespan and easier maintenance.

The buff finish has a three dimenstional feel, bringing out the shine and characteristics of aluminum. A clear coating finish is applied to strengthen corrosion-resistance for a longer wheel lifespan and easier maintenance.